What is an FPD test?

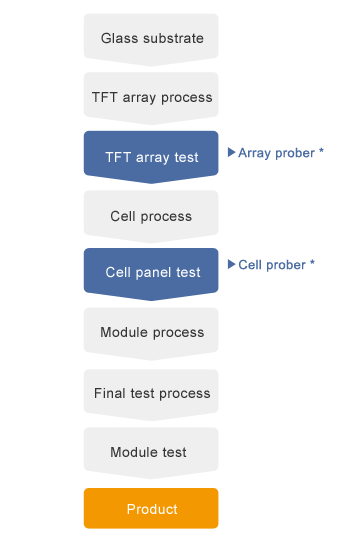

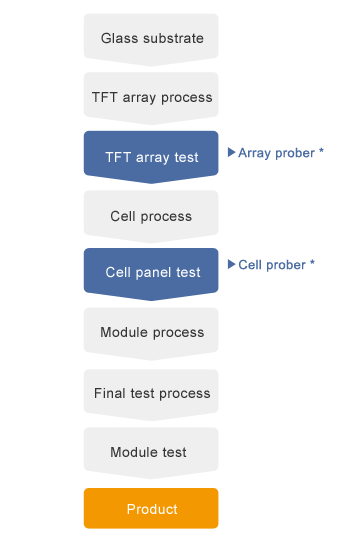

In the flat panel display (FPD) manufacturing process, tests to check panel functions and tests to evaluate the manufacturing process are conducted.

Tests in the Array Process

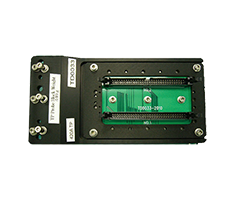

To test panel functions in the array process, an array test is conducted using an array tester, an array prober and a probe unit. This test is intended to test the functionality of the TFT array circuit formed for the panel on the glass substrate and detect any wire breakage or short circuit.

Meanwhile, to test the manufacturing process in the array process for the purpose of checking whether the manufacturing process has succeeded or failed and providing feedback to the previous process, TEG testing is conducted using a DC parametric tester, a TEG prober and a probe unit. (“TEG” stands for test element group, which comprises TFT, capacity element, wire element, and other elements of an array circuit.)

Tests in the Cell/Module Processes

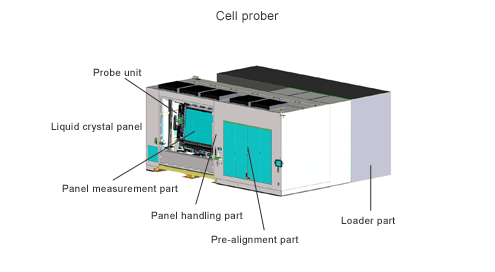

To test panel functions in the cell process and the module process, the lighting test is conducted.

Panels are activated and lit to display test patterns in order to check panel operation, dot defects, line defects, chromaticity, color mura (unevenness), contrast, etc.

There are two inspection methods: visual panel inspection by an operator and automated panel inspection using a CCD camera that automatically performs defect detection and the go/no-go test.

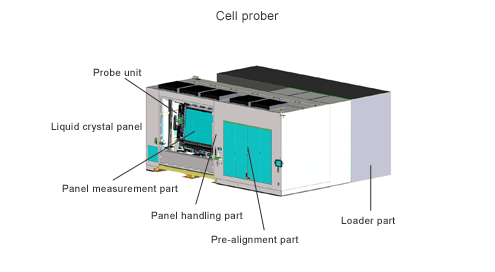

A cell tester, a cell prober and a probe unit are used for the inspection.

The module test also uses a mura inspection and compensation system that automatically detects mura or unevenness in the display and compensates light control to eliminate mura.

*We license out technologies related to array prober and cell prober products to Gallant Precision Machining Co., Ltd. (GPM) in Taiwan.

Tests in the Array Process

To test panel functions in the array process, an array test is conducted using an array tester, an array prober and a probe unit. This test is intended to test the functionality of the TFT array circuit formed for the panel on the glass substrate and detect any wire breakage or short circuit.

Meanwhile, to test the manufacturing process in the array process for the purpose of checking whether the manufacturing process has succeeded or failed and providing feedback to the previous process, TEG testing is conducted using a DC parametric tester, a TEG prober and a probe unit. (“TEG” stands for test element group, which comprises TFT, capacity element, wire element, and other elements of an array circuit.)

Tests in the Cell/Module Processes

To test panel functions in the cell process and the module process, the lighting test is conducted.

Panels are activated and lit to display test patterns in order to check panel operation, dot defects, line defects, chromaticity, color mura (unevenness), contrast, etc.

There are two inspection methods: visual panel inspection by an operator and automated panel inspection using a CCD camera that automatically performs defect detection and the go/no-go test.

A cell tester, a cell prober and a probe unit are used for the inspection.

The module test also uses a mura inspection and compensation system that automatically detects mura or unevenness in the display and compensates light control to eliminate mura.

*We license out technologies related to array prober and cell prober products to Gallant Precision Machining Co., Ltd. (GPM) in Taiwan.