What is a package probe (test socket)?

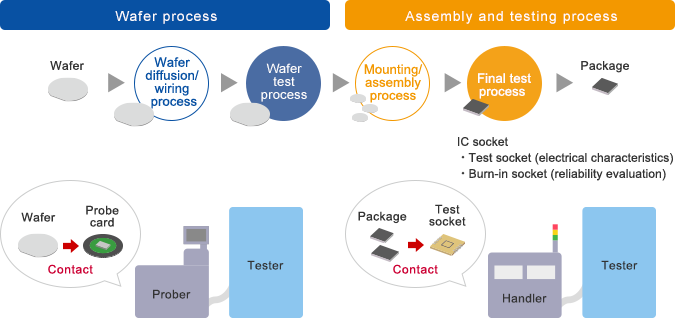

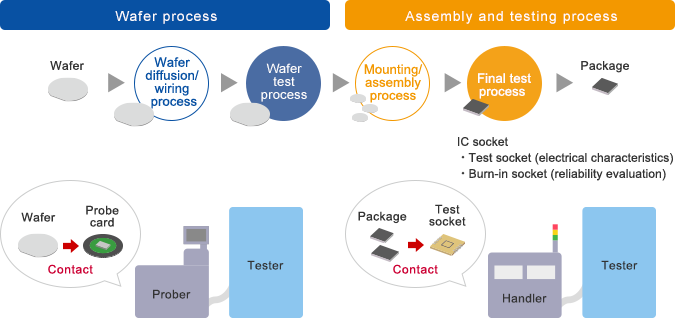

There are two important tests in semiconductor manufacturing. One is the wafer test during the wafer process, in which electrical characteristics of chips are tested before dicing a wafer into many pieces of semiconductor (called dies or chips). The other is the final test during the assembly and testing process, which is conducted after packaging the diced chips.

An IC socket is used in the final test. It plays the crucial role of connecting the device and the tester, just as a probe card does in the wafer test (see the figure below).

Depending on the purpose of the test, IC sockets are categorized into two groups: burn-in sockets for testing reliability, including durability, and test sockets for measuring electrical characteristics. Although these two types are both generally referred to as IC sockets, the required performance varies depending on the difference in use.

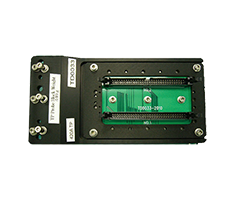

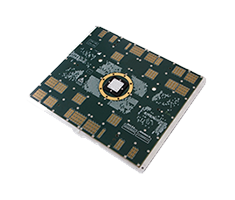

MJC provides two types of test sockets: the J-Contacts series and the BeeContacts series. Compared with conventional test sockets, these series offer higher-performance test sockets that excel in electrical characteristics, particularly high frequency characteristics and contact.

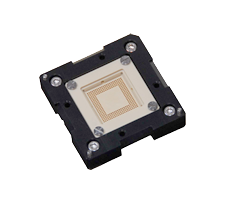

These test sockets are suitable for testing power devices and electrical parts for mobile communication and in-car devices, and are customizable according to the testing environment.

To differentiate its test sockets that probe LSI packages in a more advanced field of measurement than that of conventional products, MJC calls these “package probes.”

An IC socket is used in the final test. It plays the crucial role of connecting the device and the tester, just as a probe card does in the wafer test (see the figure below).

Depending on the purpose of the test, IC sockets are categorized into two groups: burn-in sockets for testing reliability, including durability, and test sockets for measuring electrical characteristics. Although these two types are both generally referred to as IC sockets, the required performance varies depending on the difference in use.

MJC provides two types of test sockets: the J-Contacts series and the BeeContacts series. Compared with conventional test sockets, these series offer higher-performance test sockets that excel in electrical characteristics, particularly high frequency characteristics and contact.

These test sockets are suitable for testing power devices and electrical parts for mobile communication and in-car devices, and are customizable according to the testing environment.

To differentiate its test sockets that probe LSI packages in a more advanced field of measurement than that of conventional products, MJC calls these “package probes.”