What is a wafer prober?

What is a wafer prober?

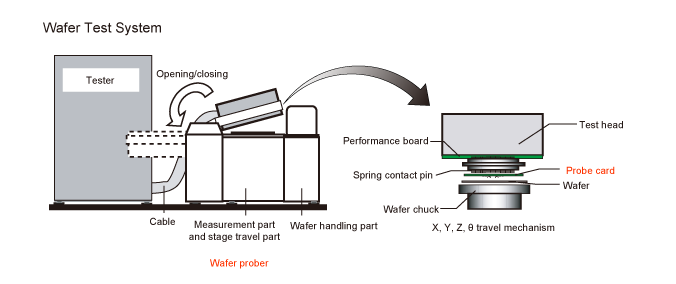

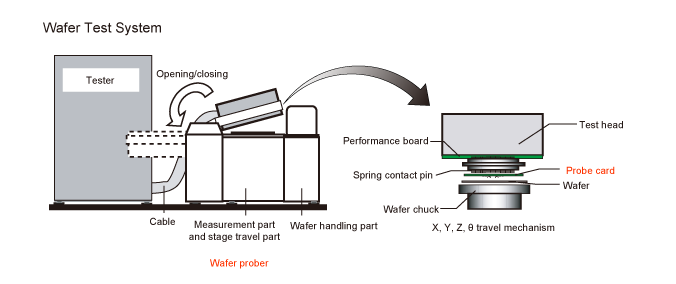

A wafer prober is a system used for electrical testing of wafers in the semiconductor development and manufacturing process.

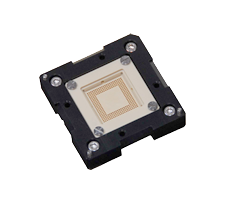

In an electrical test, test signals from a measuring instrument or tester are transmitted to individual devices on a wafer via probe needles or a probe card and the signals are then returned from the device.

A wafer prober is used for handling the wafer to make contact in the designated position on the device.

Functions Required of Wafer Probers for R&D

In semiconductor development, a wafer prober is used mainly for evaluating the characteristics of prototype ICs, reliability evaluation, and defect analysis.

In evaluating devices and processes, highly accurate measurement and evaluation of a test element group (TEG), comprising transistors, interconnections and other element devices for an IC, is conducted. This means that electrical noise and signal leakage must be prevented.

Additionally, a temperature control function is required for checking operation at low and high temperatures and for reliability evaluation. In evaluating high-power devices, high voltage and low impedance of the measurement path is also required.

Functions Required of Wafer Probers for Production Testing

Wafer testing in the semiconductor mass production process involves TEG testing for the process monitor and a go/no-go test with electrical testing of IC chips.

Functions required for wafer testing include automation of wafer handling and position control, antinoise measures, and reliability.

Moreover, high rigidity for one-touchdown with many devices and high speed control for shorter tact time, as well as availability and easy maintenance, are also crucial.

MJC's Wafer Prober

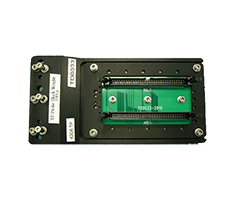

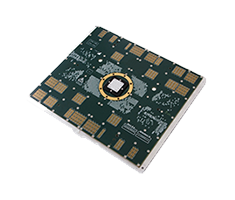

MJC's extensive lineup includes manual probers for R&D and automatic probers for production testing.

MJC will meet diverse needs for probers to improve wafer test productivity.

A wafer prober is a system used for electrical testing of wafers in the semiconductor development and manufacturing process.

In an electrical test, test signals from a measuring instrument or tester are transmitted to individual devices on a wafer via probe needles or a probe card and the signals are then returned from the device.

A wafer prober is used for handling the wafer to make contact in the designated position on the device.

Functions Required of Wafer Probers for R&D

In semiconductor development, a wafer prober is used mainly for evaluating the characteristics of prototype ICs, reliability evaluation, and defect analysis.

In evaluating devices and processes, highly accurate measurement and evaluation of a test element group (TEG), comprising transistors, interconnections and other element devices for an IC, is conducted. This means that electrical noise and signal leakage must be prevented.

Additionally, a temperature control function is required for checking operation at low and high temperatures and for reliability evaluation. In evaluating high-power devices, high voltage and low impedance of the measurement path is also required.

Functions Required of Wafer Probers for Production Testing

Wafer testing in the semiconductor mass production process involves TEG testing for the process monitor and a go/no-go test with electrical testing of IC chips.

Functions required for wafer testing include automation of wafer handling and position control, antinoise measures, and reliability.

Moreover, high rigidity for one-touchdown with many devices and high speed control for shorter tact time, as well as availability and easy maintenance, are also crucial.

MJC's Wafer Prober

MJC's extensive lineup includes manual probers for R&D and automatic probers for production testing.

MJC will meet diverse needs for probers to improve wafer test productivity.